Electric services are the backbone of modern living, supporting everything from lighting and appliances to advanced systems that keep homes and businesses running smoothly. Whether it’s a minor electrical repair or a complete system upgrade, professional electric services play a vital role in maintaining safety, efficiency, and long-term performance. Understanding what these services include and why they matter can help property owners make informed decisions and avoid costly issues.

What Electric Services Include

Electric services cover a wide range of tasks designed to install, maintain, repair, and upgrade electrical systems. These services apply to residential, commercial, and industrial settings and are essential for ensuring consistent power delivery and safe operation.

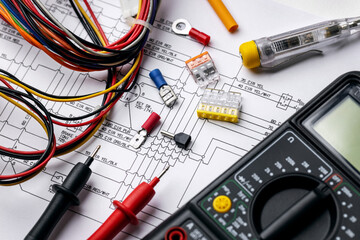

Common electric services include:

- Electrical wiring and rewiring for new or existing structures

- Installation of lighting fixtures and electrical outlets

- Panel upgrades and circuit breaker replacements

- Troubleshooting electrical faults and power issues

Each of these services is performed to ensure electrical systems meet current safety standards and operate efficiently.

The Importance of Professional Electrical Work

Electrical systems are complex and can pose serious risks if handled incorrectly. Faulty wiring, overloaded circuits, and outdated panels can lead to power failures, damaged equipment, or even fire hazards. Professional electric services help prevent these issues by ensuring that all components are installed correctly and functioning as intended.

Experienced electricians follow established safety practices and understand how to identify potential problems before they become serious. Their expertise helps protect both property and occupants while maintaining reliable power throughout the space.

Electrical Wiring and System Upgrades

Wiring is the foundation of any electrical system. Over time, wiring can deteriorate, become outdated, or fail to support increased electrical demand. Upgrading wiring is especially important in older buildings or when adding new appliances, equipment, or lighting systems.

System upgrades often include replacing outdated wiring, improving grounding, and installing additional circuits to handle modern power usage. These improvements not only enhance safety but also improve performance and reduce the risk of electrical interruptions.

Electrical Panels and Power Distribution

The electrical panel is the central hub that distributes power throughout a building. As power demands grow, panels may struggle to handle the load, leading to tripped breakers or inconsistent power. Electric services that focus on panel upgrades help ensure the system can support current and future needs.

Modern panels provide better load management and improved safety features. Upgrading a panel allows for smoother operation of appliances, reduces downtime, and creates capacity for future electrical additions.

Lighting Installation and Improvements

Lighting is a key part of both function and design. Electric services include the installation and maintenance of indoor and outdoor lighting systems that improve visibility, safety, and comfort. Proper lighting enhances productivity in work environments and creates a welcoming atmosphere in residential spaces.

Upgraded lighting solutions can also reduce energy usage and provide better illumination. From general lighting to task-focused installations, professional electricians ensure fixtures are installed correctly and positioned for maximum effectiveness.

Electrical Repairs and Troubleshooting

Electrical problems often show warning signs before becoming serious. Flickering lights, frequent breaker trips, unusual noises, or warm outlets are indicators that something may be wrong. Prompt electrical repairs help prevent minor issues from turning into major system failures.

Electricians use specialized tools and experience to diagnose problems quickly. Whether the issue is faulty wiring, a damaged outlet, or an overloaded circuit, timely repairs restore safety and reliability.

Energy Efficiency and Power Management

Modern electric services increasingly focus on improving energy efficiency. Efficient electrical systems help reduce power consumption while maintaining performance. Upgrades such as improved wiring, advanced panels, and efficient lighting solutions contribute to lower utility costs and reduced environmental impact.

Power management solutions help balance electrical loads and minimize waste. By optimizing how electricity is distributed and used, properties can operate more efficiently without sacrificing comfort or functionality.

Safety Inspections and Preventive Maintenance

Regular safety inspections are an important part of maintaining a healthy electrical system. Preventive maintenance allows electricians to identify worn components, loose connections, or outdated equipment before failures occur.

Inspections typically involve checking wiring, testing outlets, examining panels, and ensuring safety devices are functioning properly. Preventive maintenance extends the lifespan of electrical systems and helps maintain compliance with safety standards.

Electric Services for Residential Properties

In residential settings, electric services support daily living and comfort. From powering appliances and lighting to supporting home offices and entertainment systems, reliable electricity is essential. Residential electric services often include outlet installation, lighting upgrades, panel improvements, and system inspections.

As households add more devices and technology, electrical systems must adapt. Professional services help ensure homes can handle increased demand safely and efficiently.

Electric Services for Commercial Spaces

Commercial properties rely heavily on stable electrical systems to support operations, equipment, and safety systems. Electric services for businesses focus on minimizing downtime and ensuring consistent power. Services may include system expansions, lighting improvements, and regular maintenance to support productivity.

Reliable electrical infrastructure helps businesses operate smoothly while maintaining a safe environment for employees and customers.

When to Consider Electrical Upgrades

There are several signs that indicate it may be time for an electrical upgrade. Frequent power interruptions, outdated panels, insufficient outlets, or noticeable performance issues suggest the system may no longer meet current needs.

Upgrading electrical systems improves safety, supports modern technology, and enhances overall efficiency. It also adds value to a property by ensuring it meets current standards.

Electric services are essential for maintaining safe, reliable, and efficient power in any property. From wiring and lighting to repairs and system upgrades, professional electrical work supports everyday activities and long-term performance. By investing in quality electric services and regular maintenance, property owners can enjoy dependable power, improved safety, and peace of mind for years to come.